Are you a business owner looking to reduce costs and waste and enhance operational efficiency? If yes, then you must follow lean inventory management techniques. Lean Inventory techniques focus on storing only the required products in a warehouse to meet customer demands. Advanced technology like ERP software and AI can increase the efficiency of lean inventory management.

What is Lean Inventory Management?

Lean inventory management focuses on holding only the required inventories in the warehouse to meet customer demands.

When a business stores extra inventories, it occupies more space and raises the warehouse holding cost. Again, the products can become obsolete with time and lead to the loss of the business. Managing large inventories in the warehouse can even slow down the order fulfillment process.

Lean inventory management aims to eliminate wastage by reducing excess inventories in the warehouse. This approach can streamline supply chain operations and enhance operational efficiency.

Lean inventory Management examples

The popular Toyota Company introduced this concept in 1950. It receives components only when required during the production process and thus eliminates waste.

Various global e-commerce companies have utilized just-in-time inventory management techniques and have increased their profits. They use RFID technology to track inventories in real-time and restock the products when required.

Most FMCG companies combine demand forecasting and just-in-time inventory management models to reduce excess inventories inside the fulfillment center and warehouse.

Best Practices For Implementing Lean Inventory Management

The key features of lean inventory management are listed below.

1. Just in Time

JIT inventory management focuses on ordering products only when they are required for sale or production. Just-in-time inventory management eliminates the need to stock large quantities of products inside the warehouse.

2. Demand Forecasting

Demand forecasting means forecasting the product in the future. Manually demand forecasting can lead to errors. Now, AI is used by most businesses to forecast product demand accurately.

That helps to order only the required products from the supplier. Thus, demand forecasting is one of the best approaches to eliminate wastage in a business. It also helps to avoid overstock problems because we fill the stock according to the market demand.

3. Inventory Optimization

This process involves checking inventory levels regularly and adjusting if required to avoid overstocking problems.

Businesses must use ERP, warehouse and inventory management software to increase inventory visibility. Simultaneously, it should use RFID, barcodes, and IOT for real-time inventory tracking.

4. Continuous Improvement

Businesses should promote a culture of consistent improvement in all the supply chain processes. The employees need to identify the inefficiencies in storage, handling, or transportation.

They should provide warehouse solutions or implement lean practices. Regularly reviewing supply chain processes can prepare the business for challenges like storage issues and financial problems.

5. Improve Relationships With Suppliers

You should maintain strong relationships with reliable suppliers. It ensures the timely delivery of goods and materials to businesses and enhances supply chain efficiency.

6 . Warehouse Layout

You need to optimize the warehouse layout according to product demand. The inventory storage location should be easily accessible, which helps to pick up ordered products quickly. Pack them and process them for shipping. This leads to fast e-commerce order fulfillment and helps improve brand reputation.

7. Maintain Optimal Safety Stock

A business should maintain an optimal safety stock to manage supply chain disruptions. The Company needs to adjust the safety stock based on the supplier reliability. The workers should also do regular stock-out analyses to determine the risks.

Benefits Of Lean Inventory Management

There are various benefits of lean inventory management, which are listed below.

1. Reduces Cost: Lean stock management mainly focuses on reducing the business holding costs. It helps businesses become more profitable while optimizing supply chain operations.

2. Fast Order Fulfillment: Lean inventory management maintains the right amount of inventory to meet customer demand. It ensures quick order processing and provides ordered products on the customer’s doorstep within time.

3. Eco Friendly: Less wastage by following a lean stock management strategy will make your business more eco-friendly. It will reduce carbon footprints in the environment.

4. Boosts Employee morale: Overstocking products in the warehouse can cause unnecessary burdens for workers. Lean inventory management eliminates product overstocking in a warehouse. It specifies work processes and boosts employee morale.

5. Make Relationships Better With Suppliers: You need to order a small number of products from the supplier many times. This will strengthen the relationship between the business and suppliers because you connect with them more regularly.

Key Features of Lean Inventory Management

1 . Value

The value indicates the advantages that your Company will get after implementing lean inventory management principles. A business needs to understand the customer requirements and what they are willing to pay and stock products accordingly.

2. Flow

Inventories should flow seamlessly in the entire supply chain without delays or disruptions. An efficient flow ensures that goods or materials are always available when required.

3 . Pull

It is mainly associated with the just-in-time inventory management system. A business should restock the inventories or do production only when needed. This concept reduces wastage and holding costs of the business. A business can use the Kanban system to optimize inventory replenishment.

4. Perfection

Businesses should identify the inefficiencies and continuously make improvements. Techniques like KAIZEN and Six Sigma (DMAIC: Define, Measure, Analyze, Implement & control) should be implemented by a business to reduce wastage and refine inventory strategies.

Industries That Benefit The Most With Lean Inventory Management System

Various industries get to benefit from lean inventory management systems. We are listing them below.

1. Manufacturing Industries

Practicing lean stock management can reduce wastage and overproduction in manufacturing industries. For example, Toyota Company practiced the concept of just-in-time. This means the materials arrive only when they are required for production.

2. E-commerce And Retail Industry

E-commerce and retail industries use lean inventory management systems for fast order fulfillment and to reduce stock-out issues.

Examples: Amazon uses AI and real-time inventory tracking to maintain stock levels in the warehouse and fulfillment center and reduce holding costs.

3. Healthcare And Pharmaceutical

Healthcare and pharmaceutical companies use lean stock management systems to reduce expired stock. It minimizes overstocking of medicines and ensures that all the necessary drugs are available to meet patient needs.

4. Food & Beverage Industry

Food & beverage industries use lean inventory management systems to reduce spoilage. Businesses should utilize the first in, first out method to reduce waste.

Challenges And Limitations Of Lean Inventory Management

Lean inventory management offers various advantages, such as reducing logistics costs and increasing efficiency. But it provides a few limitations, too. We are listing them below.

1. High Dependency On Suppliers

Lean inventory management systems require high dependency on suppliers. Any supplier delays due to shipping and logistics problems can disrupt the entire supply chain’s efficiency. It can lead to stockout problems and decrease customer satisfaction.

2. High Risk Of Stockouts

Lean inventory focuses only on keeping the needed stock levels in the warehouse. The product demand can rise suddenly, and in such time, it can lead to stock-out issues. This can badly affect the business’s reputation in the market.

3. Initial High Investment

Practicing lean inventory management strategies requires high investment initially for demand forecasting or real-time tracking of products kept in storage. A small or medium enterprise may not have many resources to invest in such advanced technology. Outsourcing 3PL companies can help businesses to reduce their initial cost.

4. High Transportation Costs

Transporting products in small batches frequently can increase the transportation cost of the business.

5. Resistance To Change In Organization

Employees may resist adopting lean practices for various reasons, such as a lack of understanding of lean inventory management principles or fear of losing their jobs. The employees need to be fully trained regarding the lean stock management principle. Any inefficiencies can lead to errors and disrupt the entire supply chain.

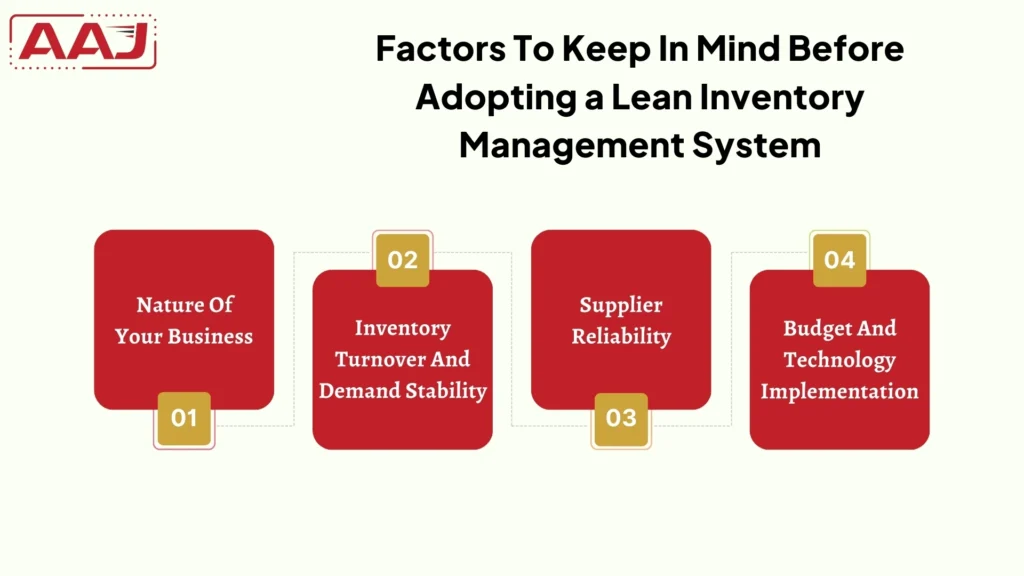

Factors To Keep In Mind Before Adopting a Lean Stock Management System

Lean inventory management offers various advantages. But that does not mean that it will be suitable for every business. You need to keep a few factors in mind before implementing the Lean system.

1. Nature Of Your Business

Lean inventory is effective for manufacturing businesses. If your company produces standardized goods with minimum customization, lean inventory principles reduce wastage.

But suppose your Company deals with more customized options or product variation. In that case, it may be challenging to apply the lean and JIT concept because of unpredictable market demand and too many SKUs.

2. Inventory Turnover And Demand Stability

If your company’s inventory turnover is fixed or customer demand is the same every time, it can benefit from lean stock management principles.

However, if your business experiences frequent demand fluctuations, lean inventory management practices can be challenging. You must keep various safeguards like safety stocks in order to meet the challenges.

3. Supplier Reliability

A strong and reliable supplier will increase efficiency in the supply chain solution. If your supplier has long lead times, it can lead to production delays and late order fulfillment.

4. Budget And Technology Implementation

Lean inventory management systems will require various tools like ERP software and automation tools for real-time tracing inventories. Leveraging these tools requires a high initial investment. If your business cannot invest in these advanced tools, a lean inventory system may not succeed. However, businesses can choose the best warehouse companies to outsource these operations.

Conclusion

Lean inventory management techniques focus on reducing wastage and delivering maximum value to the customers. However, practicing this technology requires the adoption of various technologies that will be complex for businesses. The business should also collaborate with reliable suppliers and predict product demand accurately to strengthen inventory management principles.