Inventory management is undoubtedly one of the most important aspects of business. As per the recent report by the IHL Group, companies are estimated to lose approximately $1.77 trillion annually due to mismanaged inventories. This figure reflects the total costs associated with inventory distortion, including out-of-stock and overstock.

This is a red flag on the very edge. However, adopting the approach to a good inventory system can make sure to mitigate such changes because it leads to the correct stock status, better and more timely cash flow, and profitability. One such system metric is – the inventory turnover ratio.

What is the Inventory Turnover Ratio?

The inventory turnover ratio shows the number of times a company turns over its stock in the period under consideration. This ratio helps the business to know how they control inventory and the effectiveness of the conversion of stock into sales.

A high ratio indicates good sales, while a low inventory turnover means congested or low stock space.

Why is the Inventory Ratio Important?

- Inventory Management: This helps in tracing the stock movement to make sure that you are not overloaded with stocks, as well as not short of stocks when customers make their orders.

- Cash Flow: Organizations that have a good inventory turnover ratio usually have better cash flow since little capital is tied up in unsold stock.

- Profitability: Selling inventory is typically leading to better margins and lower costs associated with inventory hold.

Inventory Turnover Ratio Formula

The formula for the inventory turnover ratio is:

Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory

Cost of Goods Sold (COGS): This is an aggregate of all costs that go into manufacturing items of sale over a given period. It consists of material that goes into production and human costs or wages paid to the employees.

Average Inventory: This is the average value of inventory a business holds over a certain tenure. You can calculate it by adding the beginning inventory and ending inventory, then dividing by 2:

Average Inventory = Beginning Inventory + Ending Inventory / 2

How to Calculate Turnover Ratio With Example?

To understand better how to calculate the Inventory Turnover Ratio step by step, let’s walk through a simple, straightforward example:

Here is a hypothetical data of a retail company:

COGS = $500,000

Beginning Inventory = $80,000

Ending inventory = $120,000

Now, to calculate the Average Inventory for this company, we’ll use the formula of average inventory calculation as given in the above section:

Average Inventory = 80,000 + 1,20,000 / 2=100,000

Now plug it in the formula of Inventory Turnover Ratio:

Inventory Turnover Ratio = 500,000 / 100,000 = 5

This indicates that the company sells and replaces its inventories five times yearly.

Ideal Inventory Turnover Ratio: What’s the Benchmark?

The best values of the inventory turnover ratio depend on the type of industry. Here’s a quick look at standard benchmarks:

- Retail Industry: A turnover ratio between 6-12 is usually preferable. Consumers are always attracted to numerous changes in the market, which causes frequent stock turnover among retailers.

- Manufacturing Companies: The rate should be 4-8 in this industry. This reflects the long time manufacturers take before they reach the consumer compared to the fast-moving consumable products.

- Grocery: An industry where 12-18 is often seen because the items are perishable and need to be sold quickly.

However, depending on the specific characteristics of the industry and specific products in a particular business, a more particular target for the inventory turnover ratio should be set.

Inventory Turnover Ratio Interpretation

Knowing your inventory turnover ratio can shed more light on your business’s performance. Let’s break it down into 2 categories:

- High Ratio: A high value (for example, 10+) indicates good sales intensity and proper warehouse storage of products. But, it also means that the stock is low, causing potential stockouts and lost sales, which will significantly impact the business.

- Low Ratio: A low ratio (below 4) may signify sales challenges or excessive stock holding. The problem with overstocking is that it leads to high holding and warehousing costs and slows the circulation of capital and cash.

The balance ratio is important to ensure the correct equilibrium. Otherwise, you would like a ratio reflecting top gross sales performance without compromising stock holding or overstretching your inventory budget. Organizations should aim for a ratio that ensures joint smooth functioning and effective cash flow efficiency.

Inventory Turnover Ratio Calculator

Companies are using an inventory turnover ratio calculator to simplify complex calculations in today’s second digital world. These virtual tools make it easier for companies to calculate inventory turnover ratios without using human calculations.

Benefits of using an inventory turnover ratio calculator:

- Time-Saving: Instant results with minimal effort.

- Accuracy: Reduces the chance of errors in manual calculations.

- Efficiency: Helps businesses make faster, data-driven decisions related to inventory management.

Many warehouse and inventory management software are already equipped with a built-in inventory turnover calculator, simplifying the process further.

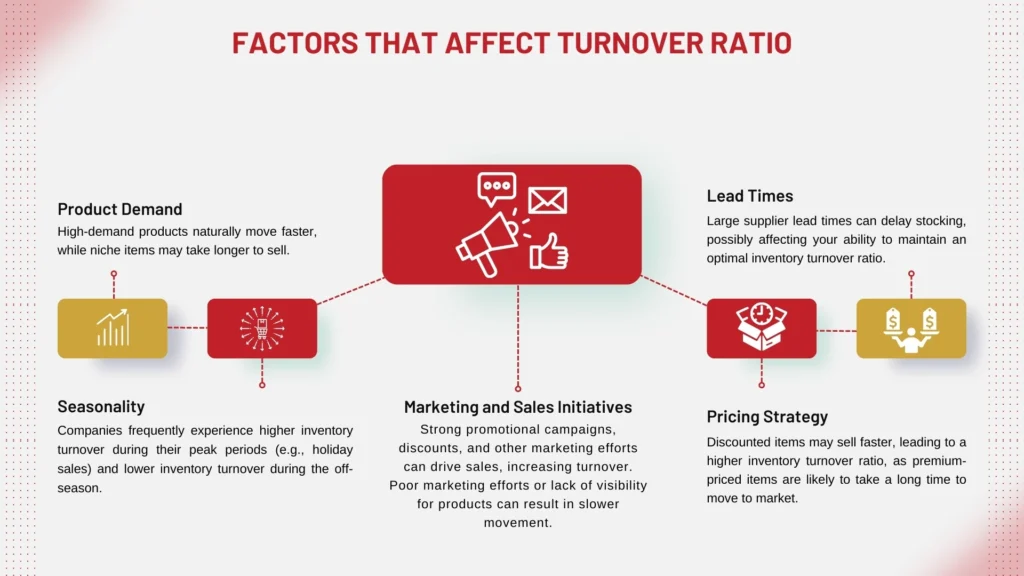

Factors That Affect Turnover Ratio

Several factors can influence a company’s inventory turnover ratio, including:

- Product Demand: High-demand products naturally move faster, while niche items may take longer to sell.

- Seasonality: Companies frequently experience higher inventory turnover during their peak periods (e.g., holiday sales) and lower inventory turnover during the off-season.

- Lead Times: Large supplier lead times can delay stocking, possibly affecting your ability to maintain an optimal inventory turnover ratio.

- Pricing Strategy: Discounted items may sell faster, leading to a higher inventory turnover ratio, as premium-priced items are likely to take a long time to move to market.

- Marketing and Sales Initiatives: Strong promotional campaigns, discounts, and other marketing efforts can drive sales, increasing turnover. Poor marketing efforts or lack of visibility for products can result in slower movement.

Tips to Improve Inventory Ratio

- Better Demand Forecasting: Use Demand Forecasting methods, data analytics, and historical sales patterns to predict upcoming demands more accurately.

- Efficient Stock Management: Implement just-in-time inventory (JIT) practices to reduce excess stock and holding costs.

The Bottom Line

In a nutshell, the inventory turnover ratio is a key metric to be closely monitored by every company. It provides insight into your inventory administration productivity, cash flow, and overall earnings potential.

Besides, you can also improve your procedures and ensure that your stocks are consistent with market demands by understanding the formula, knowing how to calculate it, and interpreting the results.

Tools like an inventory turnover calculator simplify the procedure, allowing enterprises to focus on what matters most – growing their business.