Whenever a customer orders something online, picking and packaging individual units requires a lot of effort and time. Also, businesses have to spend more money on shipping to send individual units. Kitting Service plays a crucial role in solving this picking, packaging, and shipping single unit.

Kitting is a value-added service provided by 3PL company. It combines multiple related items in a single package before storage. Whenever a customer orders, the kitting package is picked directly from the shelf, labeled properly, and shipped.

This reduces the time and effort of the warehouse staff. Kitting is used in numerous industries, such as manufacturing, electronics, healthcare, etc.

What Is Kitting In 3PL?

Kitting in 3PL is the process of grouping, packaging, and shipping multiple individual products as a single unit. Whenever kitting multiple items, it is assigned a unique SKU so that it can be managed, tracked, and fulfilled as one item instead of multiple separate parts. This 3PL process is commonly used in e-commerce, manufacturing, healthcare, and fulfillment centers to enhance efficiency, reduce errors, and streamline inventory management.

Let’s discuss this with an example. A 3PL warehouse receives various medical components like syringes, gloves, and bandages. Kitting involves assembling all the medical components into a single unit called the first aid kit before storage. Hence, this process eliminates shipping of all the individual items differently.

3PL kitting services reduce fulfillment time and improve supply chain efficiency.

Difference Between Kitting and Bundling

Both kitting and bundling terms are used interchangeably. Bundling involves selling multiple products together as a package deal, usually at a discounted price. But kitting refers to grouping various items into a single package before shipping or use. For instance, if you sell computers, you can group the CPU, motherboard, RAM, and hard drive to create a complete system.

The customer can purchase everything required to run a computer in one go without purchasing all the individual items.

But bundling is a broader term applied to grouping any items for selling. Here, numerous products are sold at a discount price to customers. Bundling can increase a business’s sales by grouping the most popular products with the slow-moving ones or the new ones. For example, you can package a printer along with an ink cartridge and sell it at a discounted price to customers.

Bundling is usually done to clear old stock or promote products that have low sales.

Both kitting and bundling are equally important in optimizing supply chain efficiency and enhancing customer experience.

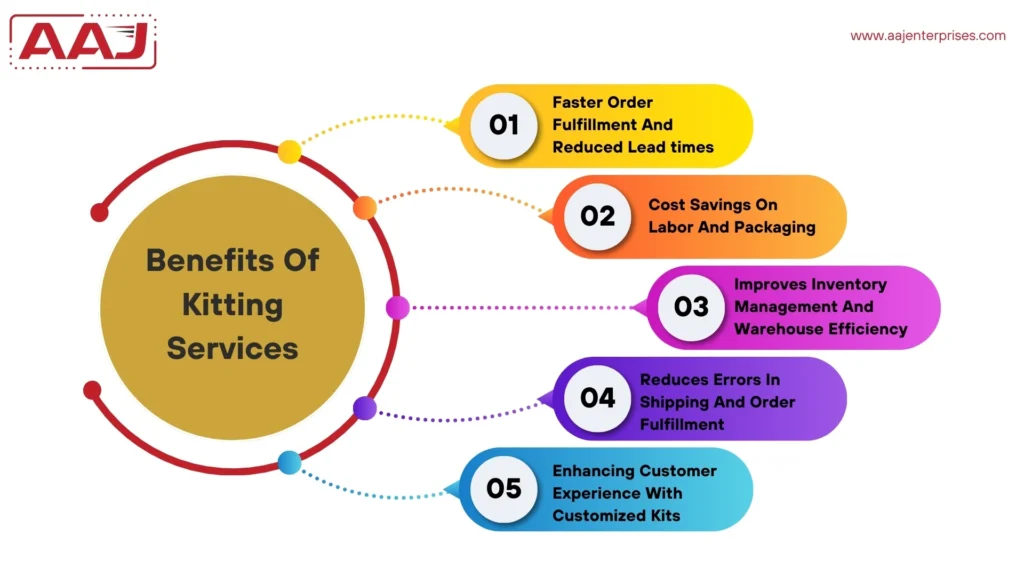

Benefits Of Kitting Services

1. Faster Order Fulfillment And Reduced Lead times

Traditional order fulfillment involves picking all the ordered products, packaging them, and then shipping every item separately. This consumes the warehouse staff’s time and effort and leads to the business’s extra logistics costs.

However, in kitting, the warehouse pre-assembles the kit in advance. So when an order is placed, the staff picks up the entire kit directly, packages it, and ships it as a single unit. This reduces the warehouse company’s time and effort. It can even fulfill orders quickly, reduce lead times, and increase customer satisfaction.

2. Cost Savings On Labor And Packaging

Kitting allows warehouse providers to design customized packaging for all the items bundled in a kit instead of packaging items separately. This reduces manual effort and, hence, the business’s labor costs.

Again, kitting products are packed compactly, reducing the dimensional weight factor. Thus, the business’s shipping and logistics costs are reduced overall.

3. Improves Inventory Management And Warehouse Efficiency

Managing multiple items can be challenging for a warehouse solution provider. Kitting in the warehouse groups various complementary items together.

It enhances stock visibility in the warehouse and reduces problems like overstocking and out-of-stock issues. The returning process is even processed faster.

Kitting even frees the warehouse storage space to store other goods and products. This organizes the warehouse better and improves the picking process.

4. Reduces Errors In Shipping And Order Fulfillment

Kitting involves pre-assembling the items in a single package. Workers pick up a prepacked kit directly from the warehouse shelf, reducing picking mistakes and increasing the packaging speed. There will be fewer errors in both shipping and ecommerce order fulfillment.

5 . Enhancing Customer Experience With Customized Kits

A well-designed, customized, and packaged kit enhances the look and feel of the product. A great unboxing experience can leave a lasting impression even on the customer’s mind.

How Does Kitting Work – Kitting Process

The warehouse will receive all the individual components that can be grouped together in a kit. The warehouse service provider will group all the items in a single kit and then place them on the shelf. Whenever the customer places an order, the entire kit is picked from the shelf, and the packaging is done according to the brand requirements. The kit is labeled with a proper shipping label and then shipped to the customer.

Role Of Warehouse Management System In Kitting

The warehouse management system tracks inventory levels and ensures that all the required products are available in the warehouse. It assigns picking tasks to the warehouse staff based on product demand. The software even generates reports on kitting efficiency and order trends.

Technology And Automation In Kitting

Technology and automation have increased the efficiency of kitting. For example, barcode scanning can quickly identify and verify items and reduce human effort. AI can identify damaged products before they are placed inside the kit.

Similarly, robotics and automatic systems can transport items automatically from the shelf to the packaging site and reduce manual effort. So, overall, technology increases the efficiency of the supply chain process.

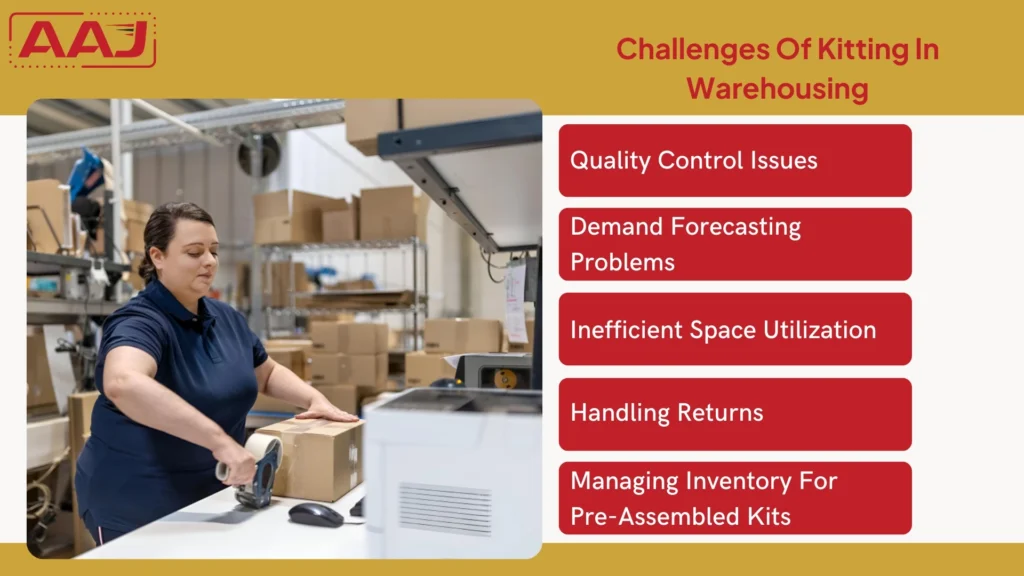

Challenges Of Kitting In Warehousing

- Quality Control Issues: It’s challenging to assemble each kit properly and consistently. Inefficiency in the kitting process can decrease customer satisfaction.

- Demand Forecasting Problems: Forecasting demand for the Kitting package in the new season can be quite challenging, and this can lead to overstocking or out-of-stock issues.

- Inefficient Space Utilization: Assembling and storing kits can occupy more space than required if not planned properly. It can disorganized the entire warehouse management.

- Handling Returns: Handling returns of knitted products involves more complications than individual returns.

- Managing Inventory For Pre-Assembled Kits: Tracking inventory both for pre-assembled kits and individual units can make it difficult to manage the kitting components. A warehouse and inventory management system can pick the individual components and finished kits without error.

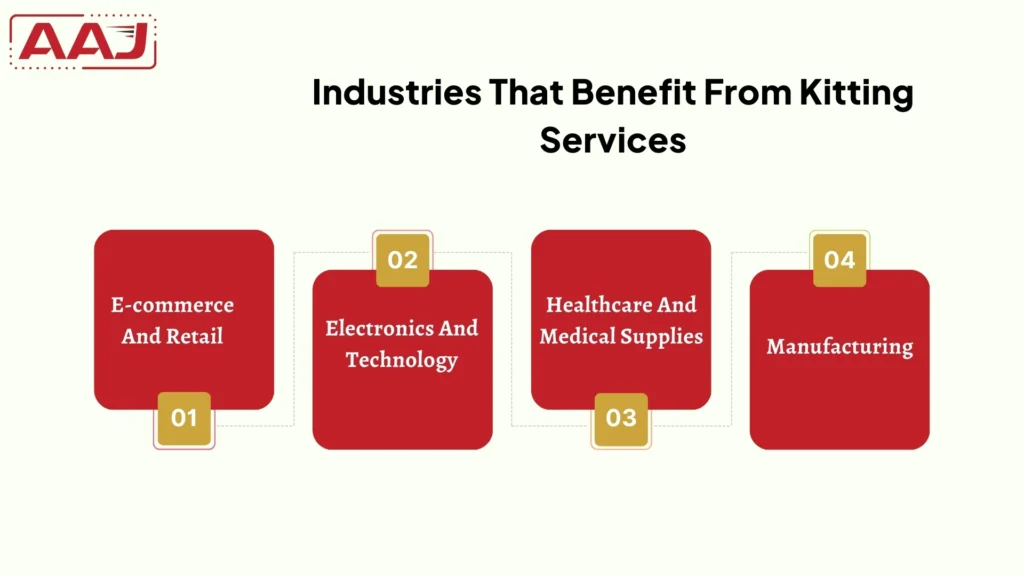

Industries That Benefit From Kitting Services

- E-commerce And Retail: Kitting speeds up the order fulfillment process and reduces packaging costs in e-commerce and retail industries.

- Electronics And Technology: Kitting simplifies the packaging and distribution of tech products.

- Healthcare And Medical Supplies: Kitting services can help pharmaceutical companies distribute prepackaged medications.

- Manufacturing: Kitting is usually used to group items that can be used to assemble a product.

Conclusion

Kitting is a strategic approach to optimizing logistics and supply chain management. It simplifies the shipping process by grouping various complimentary items in one package. A business can improve its inventory management and reduce packaging and shipping costs through kitting.